We provide reliable industrial machinery solutions tailored to your production needs, with a focus on quality, precision, and global service.

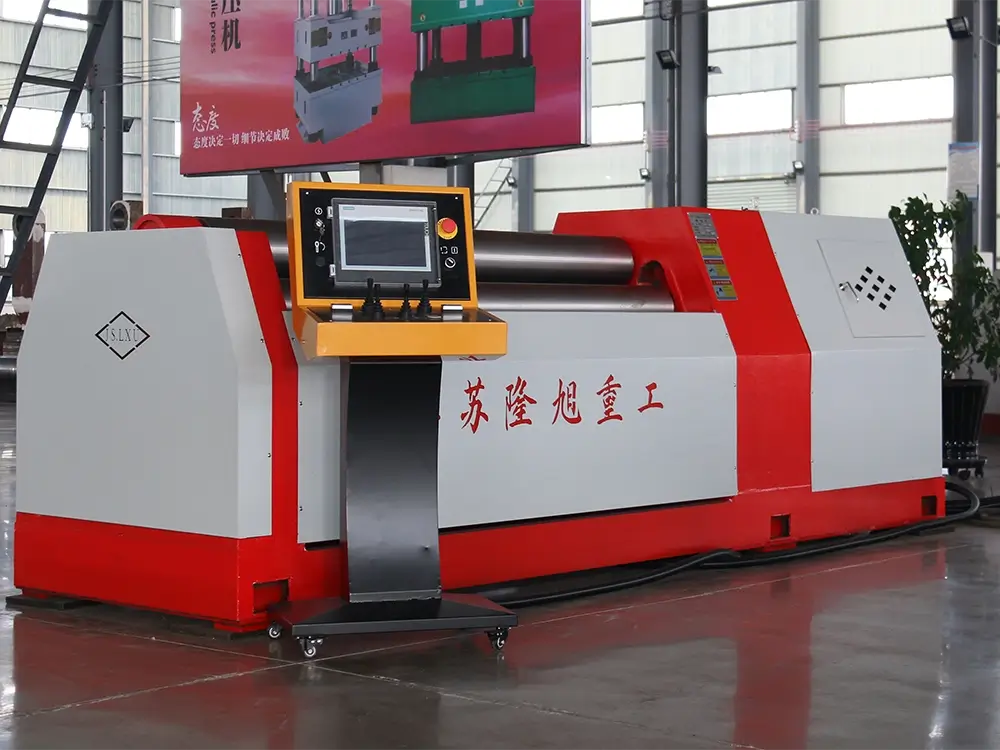

Special Rolling Machine For Oil Tank Truck

W11Y series Special rolling machine for oil tank truck has 3 symmetrical rollers. The upper roll is located at center of two lower rolls and is directly driven by dual hydraulic cylinders to move vertically. The output gear on main speed reducer is used to mesh the gears of both lower rolls for rotation so as to provide torque for rolling plate.

As your business expands, we deliver scalable solutions that grow with you. Whether you’re adding new products, entering global markets, or upgrading your technical capabilities, our tailored services are designed to support your sustainable, future-ready growth.

From streamlining workflows to enhancing overall efficiency, we offer hands-on support to optimize your daily operations. By implementing proven best practices, we help reduce costs, boost productivity, and ensure smooth performance across every stage of your business.

We collaborate closely with you to develop strategies that align with your business goals. Our team provides in-depth consultation to help you understand market trends, uncover growth opportunities, and turn insights into clear, actionable plans for long-term success.

Product Description

W11Y series Special rolling machine for oil tank truck has 3 symmetrical rollers. The upper roll is located at center of two lower rolls and is directly driven by dual hydraulic cylinders to move vertically. The output gear on main speed reducer is used to mesh the gears of both lower rolls for rotation so as to provide torque for rolling plate. Metal plate is located among three working rolls and subsequently continuously bent under pressure of upper roll and rotation of lower rolls to generate permanent plastic deformation on plate so as to roll the plate to required shape such as cylinder, taper cylinder or arc. W11Y series is not able to prebend the plate end during the rolling process,the but it can correct the roundness after welding the cylinder. The vertical moving of upper roll is monitored by a displacement sensor and shown by a digital meter, so the displacement and position of upper roll can be directly observed and working efficiency and product quality are therefore increased.

Product Features:

This Special rolling machine for oil tank truck is composed of upper roller device, lower roller device, frame, chassis, main transmission device, overturning device, supporting roller device, balance device, hydraulic system, electronic control system, etc.

The upper roller device is composed of main cylinder, upper roller bearing seat, upper roller, double row self-aligning bearing, etc.

The two main cylinders provide the pressure required for rolling sheet metal.

Double row self-aligning bearings adopt low speed and heavy load self-aligning roller bearings.

The upper roll is drum-shaped, and the load coefficient of the maximum pressure of the upper roll is 0.7 uniform load to compensate the deformation deflection of the upper roll.

The lower roll device consists of lower roll, lower roll bearing seat, lower roll input gear, lower roll sliding bearing, etc.

The main drive of the lower roller provides power, through which the output gear, the input gear and the open drive torque are transmitted to the lower roller.

The supporting roller device is composed of supporting roller, worm wheel and worm mechanism, wedge mechanism, etc.

The main transmission device consists of a main motor, a triangular belt, a cylindrical gear reducer, an electro-hydraulic push rod brake, etc. The output gear drives two lower roll gears.

The main drive can be reversed to provide rolling torque for sheet rolling.

The overturning device is composed of a sliding pillow, an overturning cylinder, etc.

Chromium plating treatment for overturned cylinder piston rod.

The overturning device is convenient for the product to be taken out along the axial direction of the roll.

Fixed, inverted frame, chassis are welded steel plate, stress removal after welding.

The balancing device consists of balancing cylinder and balancing bracket, which guarantees the balance of the upper roll and eliminates the deflection of the upper roll.

Two supporting cylinders top, balance cylinder down pressure. Keep the upper roll in a horizontal state.

Technical Parameters

No. | specifications | unit | W11Y-8*9000 | |

1 | Type | Upper roll digital display | ||

2 | Upper roller adding pressure | T | 130 | |

3 | Max width of rolling board | mm | 9000 | |

4 | The length of working roller | mm | 9100 | |

5 | Max thickness of bending plate | mm | T8*B9000*φmin1800(σs≤245MPa) | |

6 | Upper roll | Diameter | mm | Φ500 |

Material | 42CrMo | |||

Treatment | Quenching and tempering | |||

Hardness | HB260-300 | |||

7 | Lower roll | Diameter | mm | Φ260 |

Treatment | Quenching and tempering | |||

Hardness | HB260-300 | |||

8 | Distance between two down rollers | mm | 360 | |

9 | Rolling speed | m/min | About 4 | |

10 | Upper Roller Pressure Speed | mm/min | 150 mm/min | |

11 | Support rollers number | Group | 3 | |

12 | Main motor power | kW | 15 | |

13 | Hydraulic motor power | kW | 7.5 | |

After-Sales Service

Special rolling machine for oil tank truck is specially used in trailers.

One year for whole machine , any parts except consumables broken regarding machine quality within one year,We will send you the parts for free.

We will supply all the control system and software operate manual,so you can operate the machine easily refer it.

All the machine problem , you can ask us any time , we will help you solve by online way ,or tel,email,remote video at first time .

Welcome to our factory for learning how to operate machine ,one professional engineer will together with you , this service for free.

Related products

Explore our comprehensive range of high-quality metal forming machinery designed to meet diverse industrial needs.

Fully Automatic CNC Hydraulic Four Roll Plate Bending Machine

Each machine is engineered for precision, durability, and efficiency

Fully Servo CNC Four Roll Plate Rolling Machine

Each machine is engineered for precision, durability, and efficiency

3M Large Upper Roll Universal Plate Rolling Machine For Wind Power Generation

Each machine is engineered for precision, durability, and efficiency

Medium And Small Upper Roll Universal Plate Rolling Machine

Each machine is engineered for precision, durability, and efficiency

Large Hydraulic 4 Roll Plate Rolling Machine – For Thick Plate Fabrication

Each machine is engineered for precision, durability, and efficiency

Large Hydraulic Symmetric Plate Rolling Machine For Petroleum Pipeline

Each machine is engineered for precision, durability, and efficiency

Contact

We’re here to help with any questions or custom needs. Fill out the form below and our team will get back to you soon.

Get in Touch

We’re here to help with any questions or custom needs. Fill out the form below and our team will get back to you soon.

English

English  Português

Português  Русский

Русский  Español

Español  Français

Français  عربي

عربي  Tiếng Việt

Tiếng Việt  हिन्दी

हिन्दी  Indonesia

Indonesia  Türkçe

Türkçe