We provide reliable industrial machinery solutions tailored to your production needs, with a focus on quality, precision, and global service.

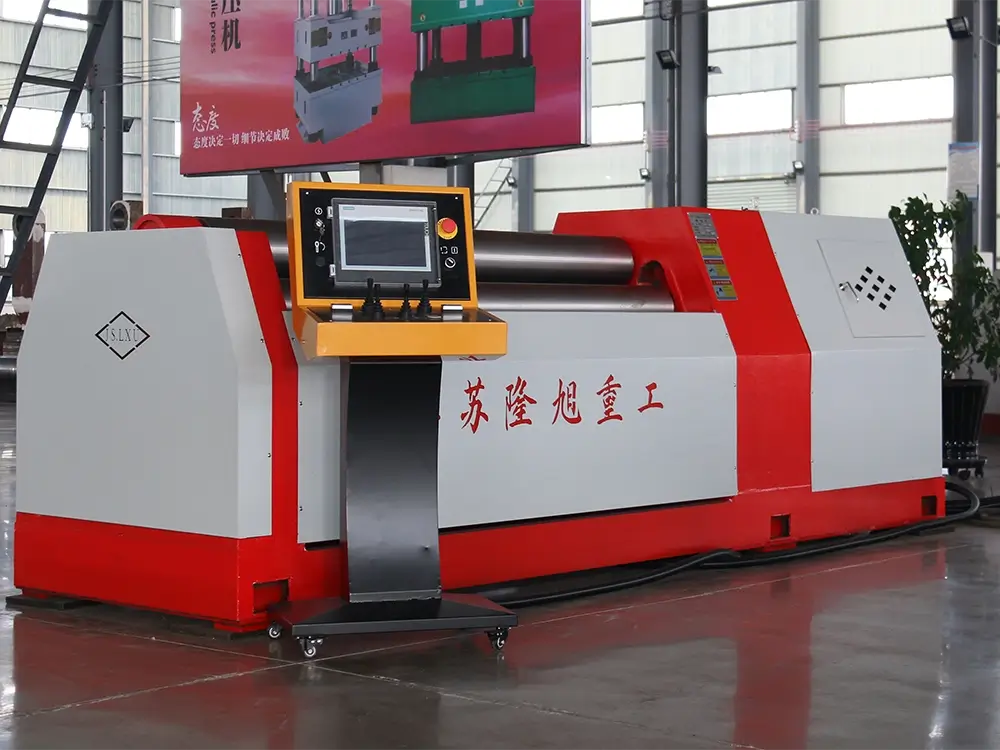

Large Hydraulic Symmetric Plate Rolling Machine For Petroleum Pipeline

This large hydraulic symmetric plate rolling machine features a 3-roller symmetrical structure, ideal for forming cylindrical, round, and conical shapes. The top roller moves vertically between two powered bottom rollers to deliver strong bending torque. Its compact design ensures reliable performance, easy operation, and low maintenance—especially suited for petroleum pipeline applications.

As your business expands, we deliver scalable solutions that grow with you. Whether you’re adding new products, entering global markets, or upgrading your technical capabilities, our tailored services are designed to support your sustainable, future-ready growth.

From streamlining workflows to enhancing overall efficiency, we offer hands-on support to optimize your daily operations. By implementing proven best practices, we help reduce costs, boost productivity, and ensure smooth performance across every stage of your business.

We collaborate closely with you to develop strategies that align with your business goals. Our team provides in-depth consultation to help you understand market trends, uncover growth opportunities, and turn insights into clear, actionable plans for long-term success.

Product Description

Large Hydraulic Symmetric Plate Rolling Machine for Petroleum Pipeline is in the form of three roller symmetry. The top roller, in the central symmetry position over the two bottom roller, does vertical motion up and down through screw, nut and worm transmission. Decelerator gears bottom rollers providing torsion moment for rolling sheet metal. The construction of the machine is compact and the operation and maintenance is convenient. It can roll cylindrical, round, and conical products.

Product Features:

The structure style of Large Hydraulic Symmetric Plate Rolling Machine for Petroleum Pipeline is 3 roller symmetrical.

The top roller do the movement of elevation in the central position of the two bottom rolls.

It's transmitted by screw nut and worm gear.two bottom rolls are main drive rolls.

They rotate by the meshing between the output gear of the gearbox and the bottom roller and supply the torque for bending plate.

It's compact easy operate and maintain.

Technical Parameters

Large Hydraulic Symmetric Plate Rolling Machine | |||||

Model | Max rolling thickness(mm) | Max rolling width(mm) | Yielding Limit of plate(Mpa) | Diameter of top roller(mm) | Main motor power |

W11Y-60×2500 | 60 | 2500 | 245 | 610 | 63 |

W11Y-80×2500 | 80 | 2500 | 245 | 720 | 75 |

W11Y-80×3200 | 80 | 3200 | 245 | 770 | 90 |

W11Y-100×3200 | 100 | 3200 | 245 | 860 | 110 |

W11Y-120×3200 | 120 | 3200 | 245 | 940 | 110 |

W11Y-150×3000 | 150 | 3000 | 245 | 1050 | 75*2 |

More models can be customized | |||||

After-Sales Service

<!--[if gte mso 9]><xml>

Large Hydraulic Symmetric Plate Rolling Machine for Petroleum Pipeline widely used in petroleum, chemical industry, boiler, shipbuilding, hydropower, metal structure and machinery manufacturing industry.

One year for whole machine , any parts except consumables broken regarding machine quality within one year,We will send you the parts for free.

We will supply all the control system and software operate manual,so you can operate the machine easily refer it.

All the machine problem , you can ask us any time , we will help you solve by online way ,or tel,email,remote video at first time .

Welcome to our factory for learning how to operate machine ,one professional engineer will together with you , this service for free.

Related products

Explore our comprehensive range of high-quality metal forming machinery designed to meet diverse industrial needs.

Fully Automatic CNC Hydraulic Four Roll Plate Bending Machine

Each machine is engineered for precision, durability, and efficiency

Fully Servo CNC Four Roll Plate Rolling Machine

Each machine is engineered for precision, durability, and efficiency

3M Large Upper Roll Universal Plate Rolling Machine For Wind Power Generation

Each machine is engineered for precision, durability, and efficiency

Medium And Small Upper Roll Universal Plate Rolling Machine

Each machine is engineered for precision, durability, and efficiency

Large Hydraulic 4 Roll Plate Rolling Machine – For Thick Plate Fabrication

Each machine is engineered for precision, durability, and efficiency

Large Hydraulic Symmetric Plate Rolling Machine For Petroleum Pipeline

Each machine is engineered for precision, durability, and efficiency

Contact

We’re here to help with any questions or custom needs. Fill out the form below and our team will get back to you soon.

Get in Touch

We’re here to help with any questions or custom needs. Fill out the form below and our team will get back to you soon.

English

English  Português

Português  Русский

Русский  Español

Español  Français

Français  عربي

عربي  Tiếng Việt

Tiếng Việt  हिन्दी

हिन्दी  Indonesia

Indonesia  Türkçe

Türkçe