We provide reliable industrial machinery solutions tailored to your production needs, with a focus on quality, precision, and global service.

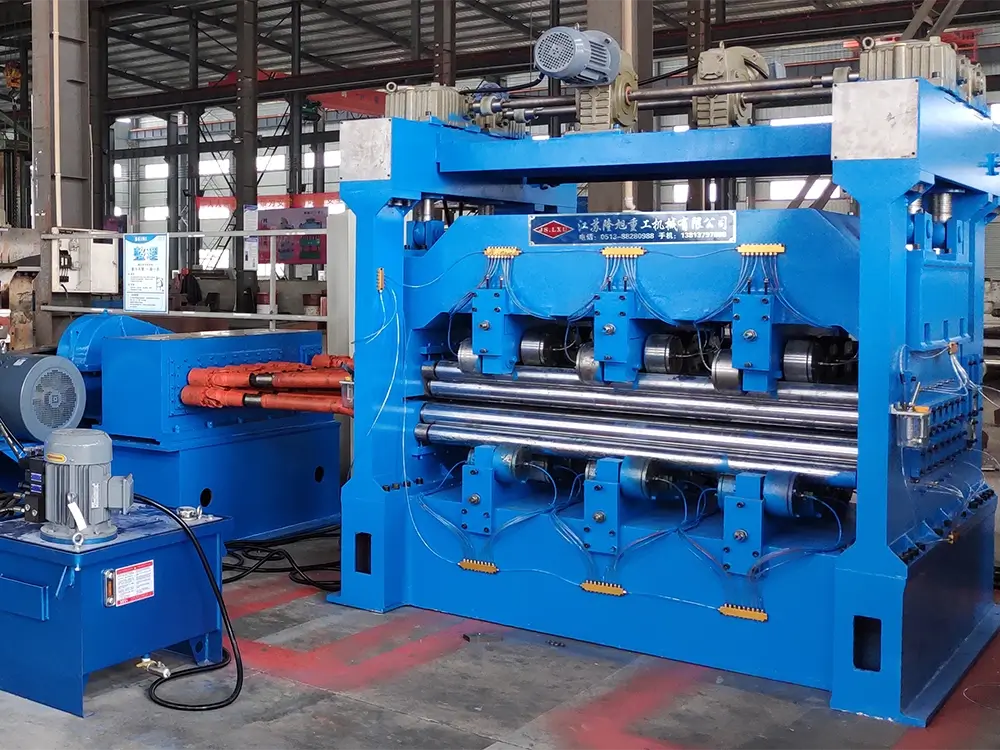

Digital Display Roll Type 13 Roll Plate Leveling Machine

Digital display roll type 13 roll plate leveling machine. This machine is cold leveling equipment for sheet metal. It can be used with various sheet and strip processing equipment to form a production line or can be used alone.

The principle of multi-roll operation is adopted to make the steel plate deform repeatedly between the leveling rolls and eliminate the stress to achieve the purpose of leveling.

Mainly applicable to metallurgy, vehicles, metal structure, ships, pressure vessels, containers, chemical machinery, and other manufacturing industries and metal materials storage, plate distribution, and other industries.

As your business expands, we deliver scalable solutions that grow with you. Whether you’re adding new products, entering global markets, or upgrading your technical capabilities, our tailored services are designed to support your sustainable, future-ready growth.

From streamlining workflows to enhancing overall efficiency, we offer hands-on support to optimize your daily operations. By implementing proven best practices, we help reduce costs, boost productivity, and ensure smooth performance across every stage of your business.

We collaborate closely with you to develop strategies that align with your business goals. Our team provides in-depth consultation to help you understand market trends, uncover growth opportunities, and turn insights into clear, actionable plans for long-term success.

Product Description

Product Features:

This machine is a W43 series standard roll plate leveler with support. It consists of a power part, a main engine part, and electronic control part.

1. Power part

The power part consists of leveling power base, reducer, YWZ brake, coupling, power distribution box, coupling bush, universal transmission shaft, etc.

The main motor is equipped with a high-power DC speed-regulating motor and analog control system, which can adjust the speed at multiple levels.

Starting current is less than rated current, starting torque is greater than rated torque, especially suitable for continuous high load start, responsible for providing leveling power to the main engine.

2. Host part

The main engine part adopts a four-fold roll assembly structure, which consists of a welding frame, integral gantry frame, 15 leveling roll shafts (top 7 bottoms 8), upper and lower roll shafts, beams, idlers, supports, worm wheel and worm drive upper roll lifting and pressing device, etc.

The leveling roll is a forging made of Gr15 and the supporting roll is made of 42CrMo. The whole frame tempering treatment, leveling work roll, supporting idler processing technology: rough turning + tempering + semi-finishing turning + intermediate frequency quenching + straightening + grinding + hard chromium plating + grinding.

To ensure that there is no radial and axial movement of the working roll, the end of the roll is connected with the roll seat by double-row heavy-duty aligning bearing, the end nuts are tightened, the hand-pressure oil pump is centralized lubricated, and the running resistance is small.

The two sides of the upper roller axle seat are arc track structures, which can adjust the gap between the inlet and outlet of the upper and lower leveling rolls.

The upper and lower rows of leveling work rolls are provided with two sets of support brackets and supporting rollers, whose height direction is adjusted by an inclined wedge to compensate for the deflection caused by the force of the leveling work rolls, to improve the strength and rigidity of the leveling work rolls (it is usually not necessary to adjust after the machine debugging is completed).

DC motor power through the coupling, reducer, power distribution box, universal joint drive shaft, and upper and lower row of work rollers connected, driving the upper and lower work rollers to actively run, high level and smoothness of sheet metal.

3. Electronic control part

The unit is centrally controlled by an electrical operating table. The electronic control part includes the operating table, DC control cabinet, and its supporting components.

It can control the parallel and reverse operation of the main motor, adjust the leveling speed, adjust the gap between the upper and lower rollers as a whole, and adjust the gap between the import and export separately.

The power supply is 380V, 50HZ AC power supply, and the ambient temperature is -10℃~40℃.

4. Main configuration

1. Bearing Wafangdian

2. Main motor Jiangsu

3. Main Electrical Component Siemens

4. Reducer Jiangsu

Technical Parameters

1. Leveling thickness: 2-6mm

2. Leveling width: 1350mm

3. Number of leveling rollers: 15

4. Diameter of leveling roll: 115 mm

5. Leveling speed: 0-10m/min

6. Leveling smoothness: +1mm/(plate thickness 2-6)

7. Applicable Material: 304 Stainless Steel (Other Material Converted by Its Strength)

8. Main motor power: 37KW

9. Hardness of work roll: 55-60HRC, hardening depth 5-8.

10. Quenching hardness of support roll: 50-55HRC, hardening depth 4-6 mm,

More models can be customized

After-Sales Service

One year for the whole machine, any parts except consumables broken regarding machine quality within one year, We will send you the parts for free.

We will supply all the control systems and software operation manual, so you can operate the machine easily refer to it.

Machine problem, you can ask us any time, and we will help you solve it by the online way, tel, email, or remote video for the first time.

Welcome to our factory for learning how to operate the machine, one professional engineer will together with you, this service for free.

Related products

Explore our comprehensive range of high-quality metal forming machinery designed to meet diverse industrial needs.

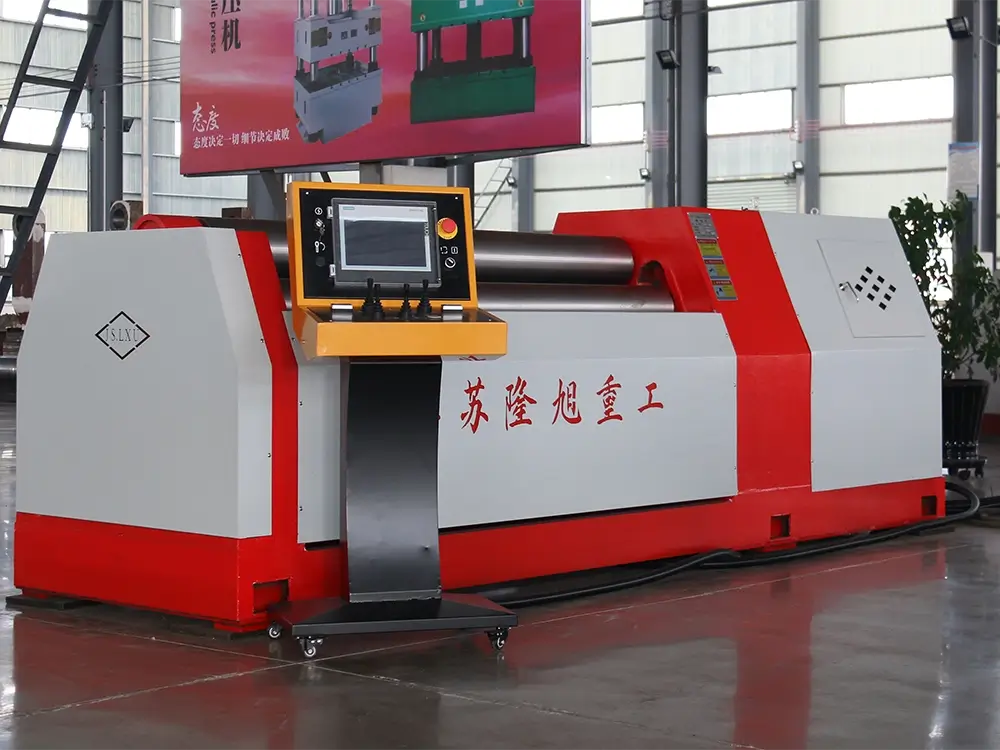

Fully Automatic CNC Hydraulic Four Roll Plate Bending Machine

Each machine is engineered for precision, durability, and efficiency

Fully Servo CNC Four Roll Plate Rolling Machine

Each machine is engineered for precision, durability, and efficiency

3M Large Upper Roll Universal Plate Rolling Machine For Wind Power Generation

Each machine is engineered for precision, durability, and efficiency

Medium And Small Upper Roll Universal Plate Rolling Machine

Each machine is engineered for precision, durability, and efficiency

Large Hydraulic 4 Roll Plate Rolling Machine – For Thick Plate Fabrication

Each machine is engineered for precision, durability, and efficiency

Large Hydraulic Symmetric Plate Rolling Machine For Petroleum Pipeline

Each machine is engineered for precision, durability, and efficiency

Contact

We’re here to help with any questions or custom needs. Fill out the form below and our team will get back to you soon.

Get in Touch

We’re here to help with any questions or custom needs. Fill out the form below and our team will get back to you soon.

English

English  Português

Português  Русский

Русский  Español

Español  Français

Français  عربي

عربي  Tiếng Việt

Tiếng Việt  हिन्दी

हिन्दी  Indonesia

Indonesia  Türkçe

Türkçe