We provide reliable industrial machinery solutions tailored to your production needs, with a focus on quality, precision, and global service.

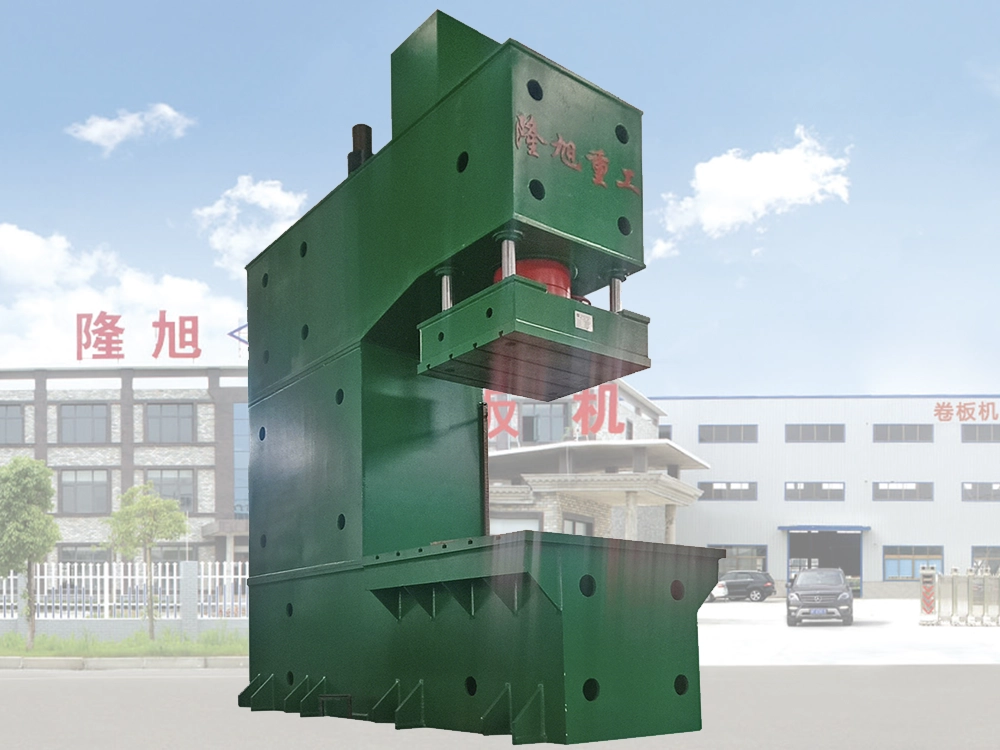

Large Single Column Straightening Hydraulic Press

The large single-column straightening hydraulic press, The main body, the sliding block, and workbench are important components of the single-arm hydraulic press.

The hydraulic oil cylinder is installed in the hole of the supporting cylinder plate of the main body. The sliding block is connected with the connecting flange of the piston rod of the main oil cylinder and is guided to move up and down through the guide column.

The lower part of the main machine is installed with the workbench plate. The sliding block and workbench surface are provided with a "T" shaped groove, which is convenient for users to fasten and install the mold.

As your business expands, we deliver scalable solutions that grow with you. Whether you’re adding new products, entering global markets, or upgrading your technical capabilities, our tailored services are designed to support your sustainable, future-ready growth.

From streamlining workflows to enhancing overall efficiency, we offer hands-on support to optimize your daily operations. By implementing proven best practices, we help reduce costs, boost productivity, and ensure smooth performance across every stage of your business.

We collaborate closely with you to develop strategies that align with your business goals. Our team provides in-depth consultation to help you understand market trends, uncover growth opportunities, and turn insights into clear, actionable plans for long-term success.

Product Description

The large single-column straightening hydraulic press, The main body, the sliding block, and workbench are important components of the single-arm hydraulic press.

The hydraulic oil cylinder is installed in the hole of the supporting cylinder plate of the main body. The sliding block is connected with the connecting flange of the piston rod of the main oil cylinder and is guided to move up and down through the guide column.

The lower part of the main machine is installed with the workbench plate. The sliding block and workbench surface are provided with a "T" shaped groove, which is convenient for users to fasten and install the mold.

The single-arm hydraulic press is optimized by computer design. It adopts an overall welding structure. The main force-bearing part is added with rib plates. The stress distribution is reasonable after being stressed, with good rigidity and high strength.

The material is a high-quality Q235 steel plate, which is cut by semi-automatic flame cutting, assembled, welded by gas-shielded welding, and mechanically processed after vibration aging or tempering treatment.

The sliding block and the worktable plate are made of a whole steel plate, and the upper and lower parts are finished with T-grooves.

The slider movement is guided by four guide pillars. The guide is made of 45 # round steel by machining, which has sufficient strength and stiffness.

The guide surface of the guide pillar is plated with hard chromium, which has high precision, good hardness, and a beautiful surface. The guide sleeve is embedded in the guide hole of the main engine body cylinder support plate.

The guide sleeve is HT200, embedded with a bronze guide belt, with good wear resistance and high guidance accuracy. The upper part of the guide sleeve is equipped with a special dust ring to prevent dust and dirt from entering the inner surface of the guide sleeve.

Product Features:

1. The steel plate is welded to the fuselage, which has higher strength and stiffness. The solid open structure with integral welding is adopted, which can keep the fuselage rigid enough.

2. The C-type body is convenient for mold installation and processing of large-size materials.

3. Economical and durable, simple structure, good universality, convenient maintenance, and operation.

4. The single-arm hydraulic press can expand the working range according to the demand, and extend the stroke of the hydraulic cylinder by using the three side space (optional), so it has a very convenient operating space.

5. Hydraulic system radiator (optional).

6. There are two control modes, manual control and semi-automatic control. The pressing upper mold can be stopped within any range of travel manually. It is equipped with an emergency recovery button, and an infrared handguard can also be added.

7. The press mounting stroke of a single-arm hydraulic press is generally controlled by a timer, pressure switch, position sensor, or customer's own mold.

8. The lifting height of the press mounting spindle can be adjusted within any range of travel through the timer or position sensor.

9. The pressure, stroke, pressure holding time, and closing height can be adjusted by the customer, which is convenient for operation.

10. With an automatic counting function, a force measuring display and intelligent temperature controller can also be added, which can be customized according to customer requirements

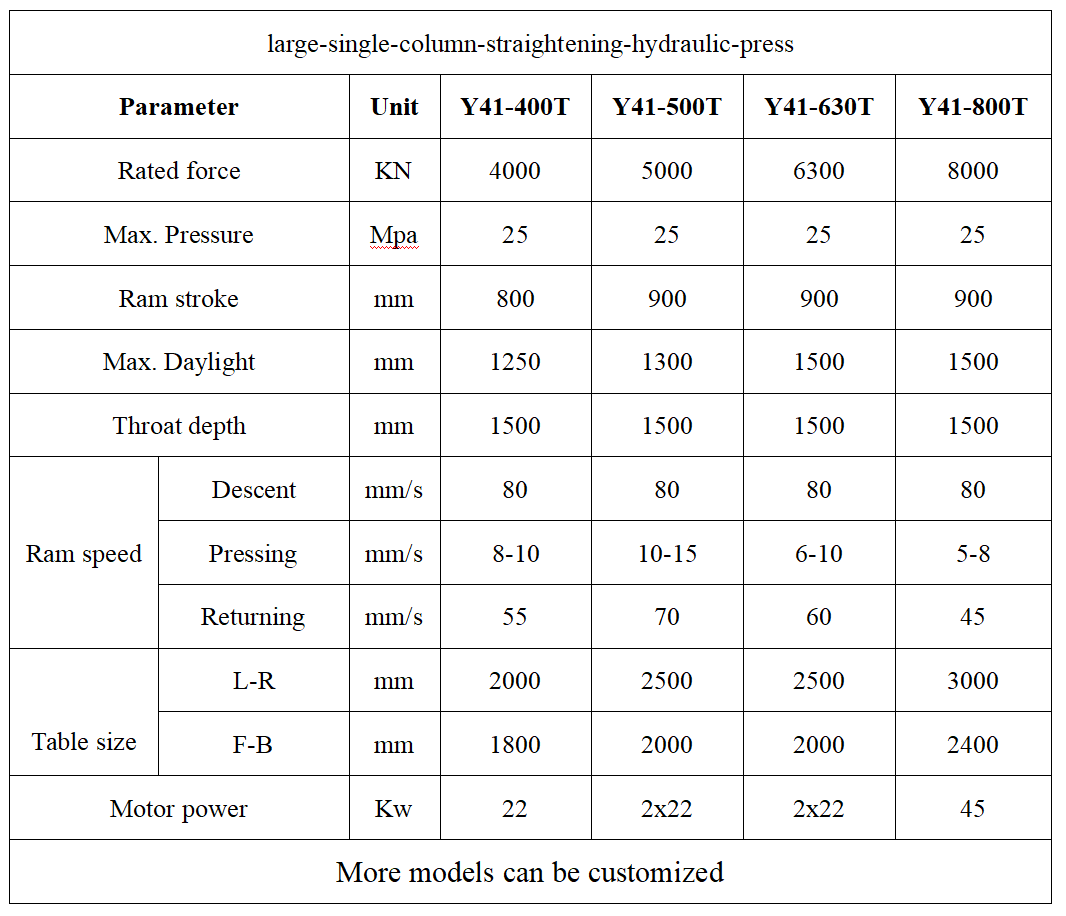

Technical Parameters

After-Sales Service

One year for the whole machine, any parts except consumables broken regarding machine quality within one year, We will send you the parts for free.

We will supply all the control systems and software operation manual, so you can operate the machine easily refer to it.

For machine problems, you can ask us any time, we will help you solve by the online way , or tel, email, or remote video the first time.

Welcome to our factory for learning how to operate the machine, one professional engineer will together with you, this service for free.

Related products

Explore our comprehensive range of high-quality metal forming machinery designed to meet diverse industrial needs.

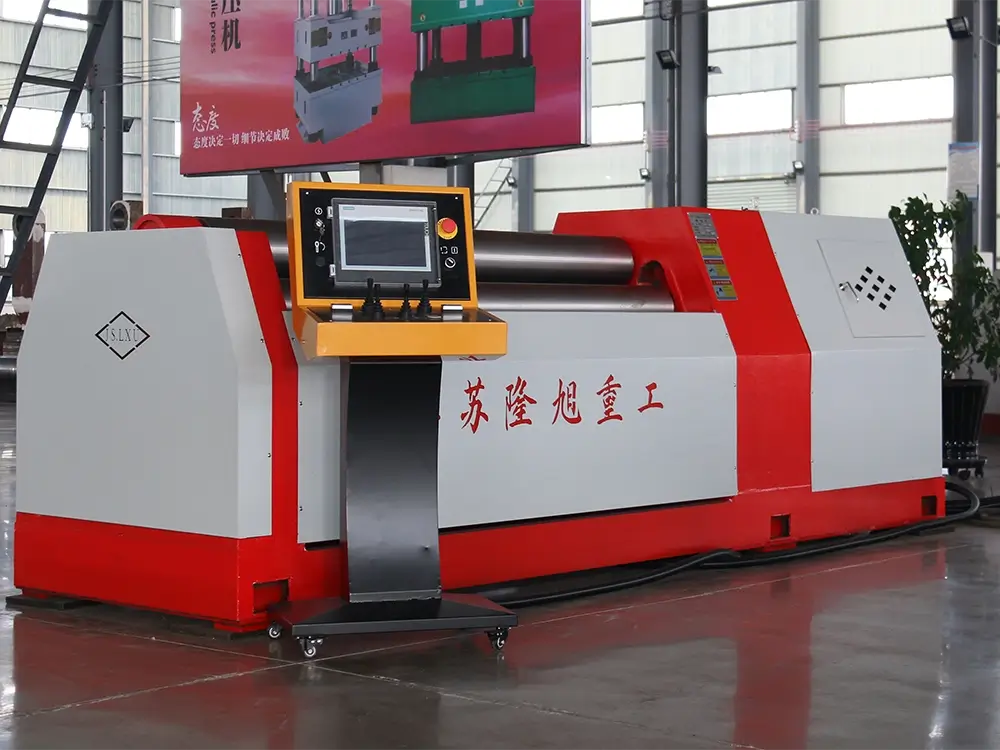

Fully Automatic CNC Hydraulic Four Roll Plate Bending Machine

Each machine is engineered for precision, durability, and efficiency

Fully Servo CNC Four Roll Plate Rolling Machine

Each machine is engineered for precision, durability, and efficiency

3M Large Upper Roll Universal Plate Rolling Machine For Wind Power Generation

Each machine is engineered for precision, durability, and efficiency

Medium And Small Upper Roll Universal Plate Rolling Machine

Each machine is engineered for precision, durability, and efficiency

Large Hydraulic 4 Roll Plate Rolling Machine – For Thick Plate Fabrication

Each machine is engineered for precision, durability, and efficiency

Large Hydraulic Symmetric Plate Rolling Machine For Petroleum Pipeline

Each machine is engineered for precision, durability, and efficiency

Contact

We’re here to help with any questions or custom needs. Fill out the form below and our team will get back to you soon.

Get in Touch

We’re here to help with any questions or custom needs. Fill out the form below and our team will get back to you soon.

English

English  Português

Português  Русский

Русский  Español

Español  Français

Français  عربي

عربي  Tiếng Việt

Tiếng Việt  हिन्दी

हिन्दी  Indonesia

Indonesia  Türkçe

Türkçe