We provide reliable industrial machinery solutions tailored to your production needs, with a focus on quality, precision, and global service.

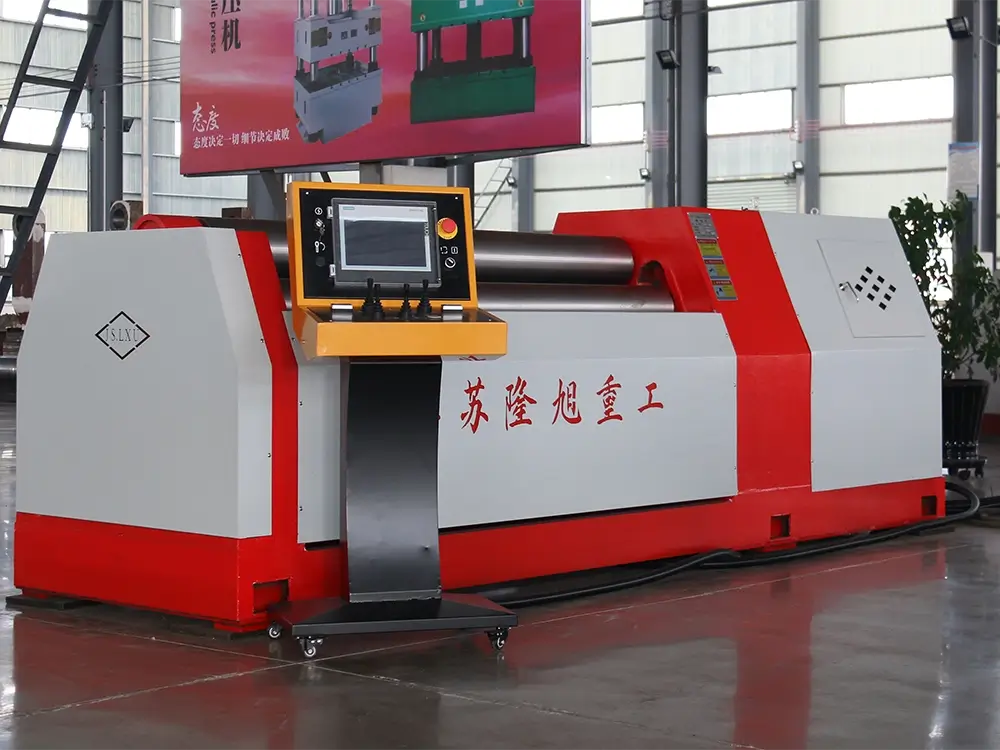

Three roll ship plat bending machine

Hydraulic upward regulating marine three roll plate rolling machine is used to roll various containers of carbon steel and low-alloy steel into circular arc workpieces at room temperature.

The frame and chassis are welded steel plates, which undergo annealing to remove stress and shot peening treatment after welding.

The upper and lower rollers are made of 42CrMo forged parts, which are quenched and tempered HB260-300 after rough machining.

The upper part of the upper roller is equipped with a rigid beam, and there are multiple sets of rollers between the beam and the upper roller to improve the rigidity of the upper roller.

As your business expands, we deliver scalable solutions that grow with you. Whether you’re adding new products, entering global markets, or upgrading your technical capabilities, our tailored services are designed to support your sustainable, future-ready growth.

From streamlining workflows to enhancing overall efficiency, we offer hands-on support to optimize your daily operations. By implementing proven best practices, we help reduce costs, boost productivity, and ensure smooth performance across every stage of your business.

We collaborate closely with you to develop strategies that align with your business goals. Our team provides in-depth consultation to help you understand market trends, uncover growth opportunities, and turn insights into clear, actionable plans for long-term success.

Product Description

Hydraulic upward regulating marine three roll plate rolling machine is used to roll various containers of carbon steel and low-alloy steel into circular arc workpieces at room temperature.

The frame and chassis are welded steel plates, which undergo annealing to remove stress and shot peening treatment after welding.

The upper and lower rollers are made of 42CrMo forged parts, which are quenched and tempered HB260-300 after rough machining.

The upper part of the upper roller is equipped with a rigid beam, and there are multiple sets of rollers between the beam and the upper roller to improve the rigidity of the upper roller.

At the same time, multiple sets of rollers are also installed at the lower part of the lower roller to improve its stiffness.

The main transmission device consists of a main motor, a reducer, a brake, etc. The output gear drives the two lower rollers to rotate in both directions, providing winding torque for the sheet metal.

The hydraulic system drives the main oil cylinder to provide the required pressure for rolling the sheet metal.

The equipment electrical control system consists of an electrical control cabinet, an operation console, and a handheld remote control. The remote control is equipped with buttons to control the actions of various parts of the machine, making it easy to operate.

Product Features:

The main structure of the equipment consists of an upper roller and upper support roller device, a lower roller device, a lower support roller device, a main transmission device, left and right side frames, a chassis and beam, feeding, hydraulic, electrical, etc.

Upper roller device

The upper roller and upper support roller device consist of a main oil cylinder, upper support roller, upper roller bearing seat, upper roller, double row self-aligning bearings, etc.

The two main oil cylinders provide the required pressure for rolling the sheet metal, and the working pressure of the main oil cylinder is 19.5 MPa.

Double row self-aligning bearings use low-speed, heavy-duty self-aligning roller bearings.

The upper roll is made of alloy steel, which is quenched and tempered HB260-300 after rough machining,

Lower roller device

The lower roller device consists of a lower roller, a lower roller bearing seat, a lower roller input gear, a lower roller sliding bearing, etc.

The lower roll is made of alloy steel, and HB260-300 is quenched and tempered after rough machining. According to JB/ZG4289-86 roller steel standard, SF-1 self-lubricating composite material is selected for the lower roll sliding bearing.

The main transmission of the lower roller provides power, which is transmitted through the output gear of the main transmission, the input gear of the lower roller, and the open transmission torque to the lower roller.

Lower roller device

The roller device consists of a roller, a mother screw mechanism, a wedge mechanism, etc.

The material of the roller is 45 steel, quenched and tempered, with a hardness of HB190~220. The surface hardness of the roller is lower than that of the lower roller. There are four rollers in each group, and they are adjusted up and down according to the load size of the rolled plate specifications.

The activity material baffle is lifted up and down by an oil cylinder.

main drive

The main transmission device consists of a main motor, a V-belt, a cylindrical gear reducer, an electro-hydraulic push rod brake, etc. The output gear drives two lower roller gears. The main drive can rotate in both forward and reverse directions, providing winding torque for the sheet metal.

Left and right side racks, chassis

The frame and chassis are welded steel plates, which undergo annealing to remove stress and shot peening treatment after welding.

The chassis adopts a frame structure, with a high anti torsion section coefficient, few anchor bolts, and easy installation and debugging.

beam

The main beam is a welded steel plate component, which undergoes stress removal and surface rust prevention treatment after welding

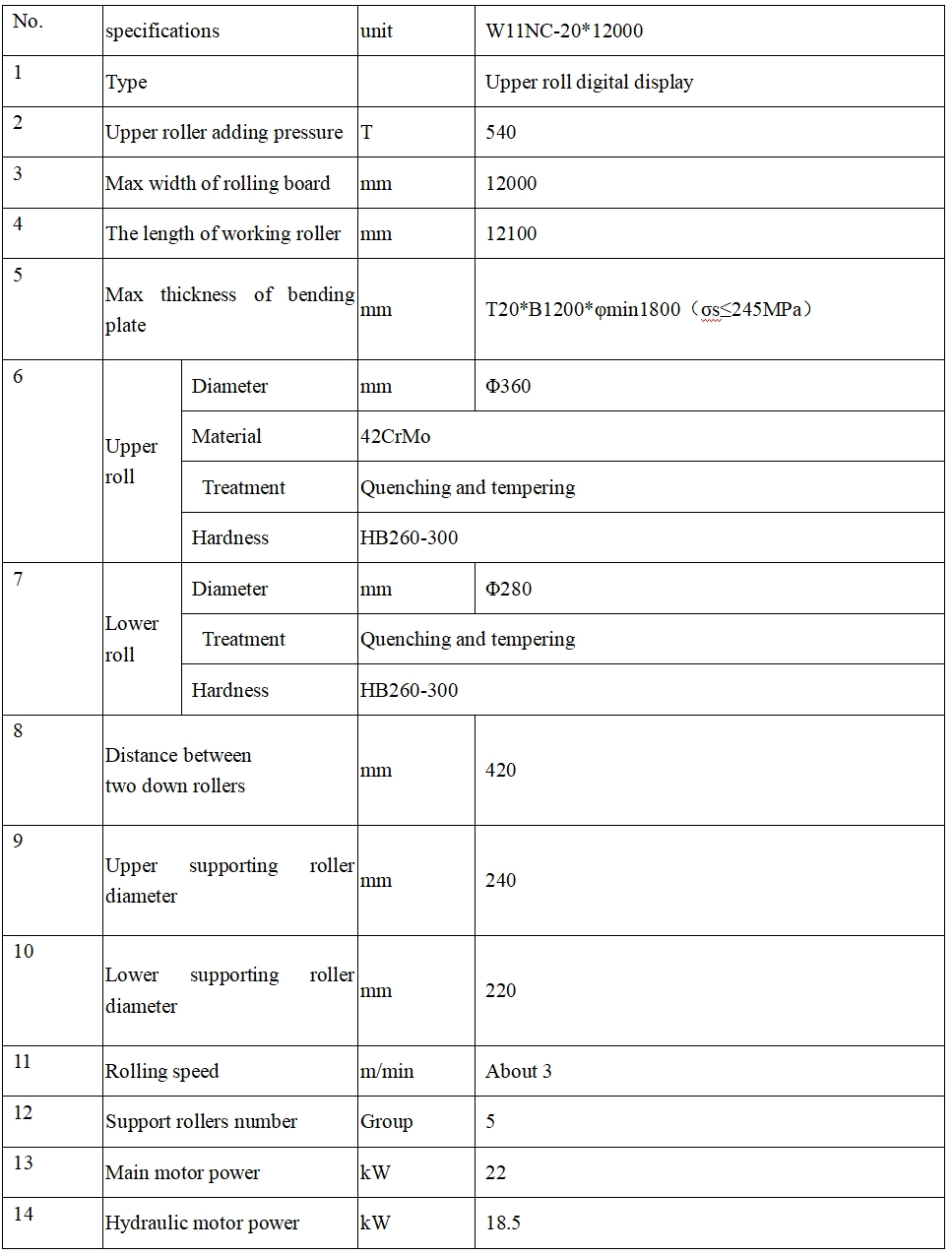

Technical Parameters

After-Sales Service

One year for whole machine , any parts except consumables broken regarding machine quality within one year,We will send you the parts for free.

We will supply all the control system and software operate manual,so you can operate the machine easily refer it.

All the machine problem , you can ask us any time , we will help you solve by online way ,or tel,email,remote video at first time .

Welcome to our factory for learning how to operate machine ,one professional engineer will together with you , this service for free.

Related products

Explore our comprehensive range of high-quality metal forming machinery designed to meet diverse industrial needs.

Fully Automatic CNC Hydraulic Four Roll Plate Bending Machine

Each machine is engineered for precision, durability, and efficiency

Fully Servo CNC Four Roll Plate Rolling Machine

Each machine is engineered for precision, durability, and efficiency

3M Large Upper Roll Universal Plate Rolling Machine For Wind Power Generation

Each machine is engineered for precision, durability, and efficiency

Medium And Small Upper Roll Universal Plate Rolling Machine

Each machine is engineered for precision, durability, and efficiency

Large Hydraulic 4 Roll Plate Rolling Machine – For Thick Plate Fabrication

Each machine is engineered for precision, durability, and efficiency

Large Hydraulic Symmetric Plate Rolling Machine For Petroleum Pipeline

Each machine is engineered for precision, durability, and efficiency

Contact

We’re here to help with any questions or custom needs. Fill out the form below and our team will get back to you soon.

Get in Touch

We’re here to help with any questions or custom needs. Fill out the form below and our team will get back to you soon.

English

English  Português

Português  Русский

Русский  Español

Español  Français

Français  عربي

عربي  Tiếng Việt

Tiếng Việt  हिन्दी

हिन्दी  Indonesia

Indonesia  Türkçe

Türkçe