A four roll plate rolling machine is an advanced piece of equipment used to bend and shape metal plates into cylindrical, conical, or custom curved components. It is widely used in industries such as pressure vessel fabrication, boiler manufacturing, shipbuilding, and steel structure production.

Structure and Working Principle

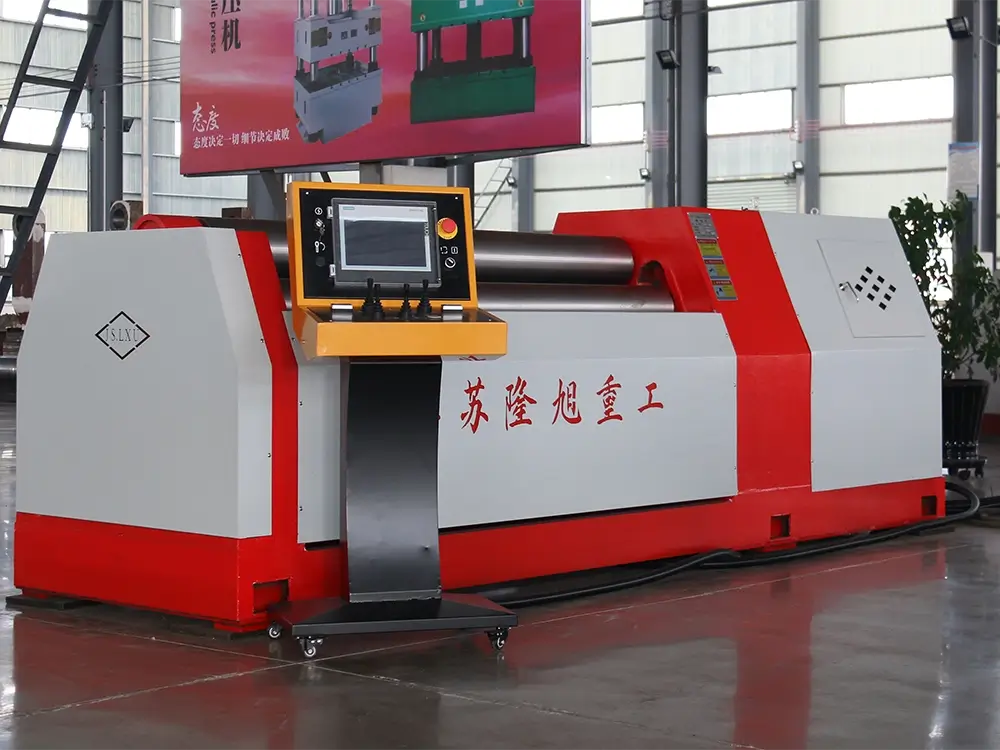

The machine consists of:

One fixed upper roller

One adjustable lower roller (driven)

Two side rollers (movable)

The upper and lower rollers are both powered, providing strong and stable rolling force. The side rollers move diagonally under hydraulic pressure to create precise bending curves. The lower roller lifts the plate to pinch it against the upper roller, and the side rollers then shape the plate as it feeds through.

This configuration allows for pre-bending, rolling, and rounding to be completed in one operation—offering higher efficiency and accuracy compared to three-roll machines.

Key Features of LONGXU Four Roll Machines:

Hydraulic double drive: Ensures strong rolling force for thick plates

CNC or semi-automatic control: Improves precision and repeatability

Forged, hardened rollers: Withstand high pressure and extend service life

Movable operator panel: Easy control and flexible operation

Overload protection & lubrication system: Ensures safety and low maintenance

Whether forming complete cylinders or partial curves, the four roll design is especially suitable for medium to heavy-duty plate forming tasks.

English

English  Português

Português  Русский

Русский  Español

Español  Français

Français  عربي

عربي  Tiếng Việt

Tiếng Việt  हिन्दी

हिन्दी  Indonesia

Indonesia  Türkçe

Türkçe